ZGWM wheels are Fully Forged with an industry leading 10,000 Tons of pressure. That means ZGWM wheels are strong, light, durable all in one. That’s not all, we employ state of the art technologies to give you features that make sure you stay on top of your performance game.

Not all wheels are created equal.

All ZGWM Forged wheels feature a gear cut knurled bead seat which improves the bind between the tire and the rim. This prevents tire creep / slippage and improves traction in high performance driving conditions.

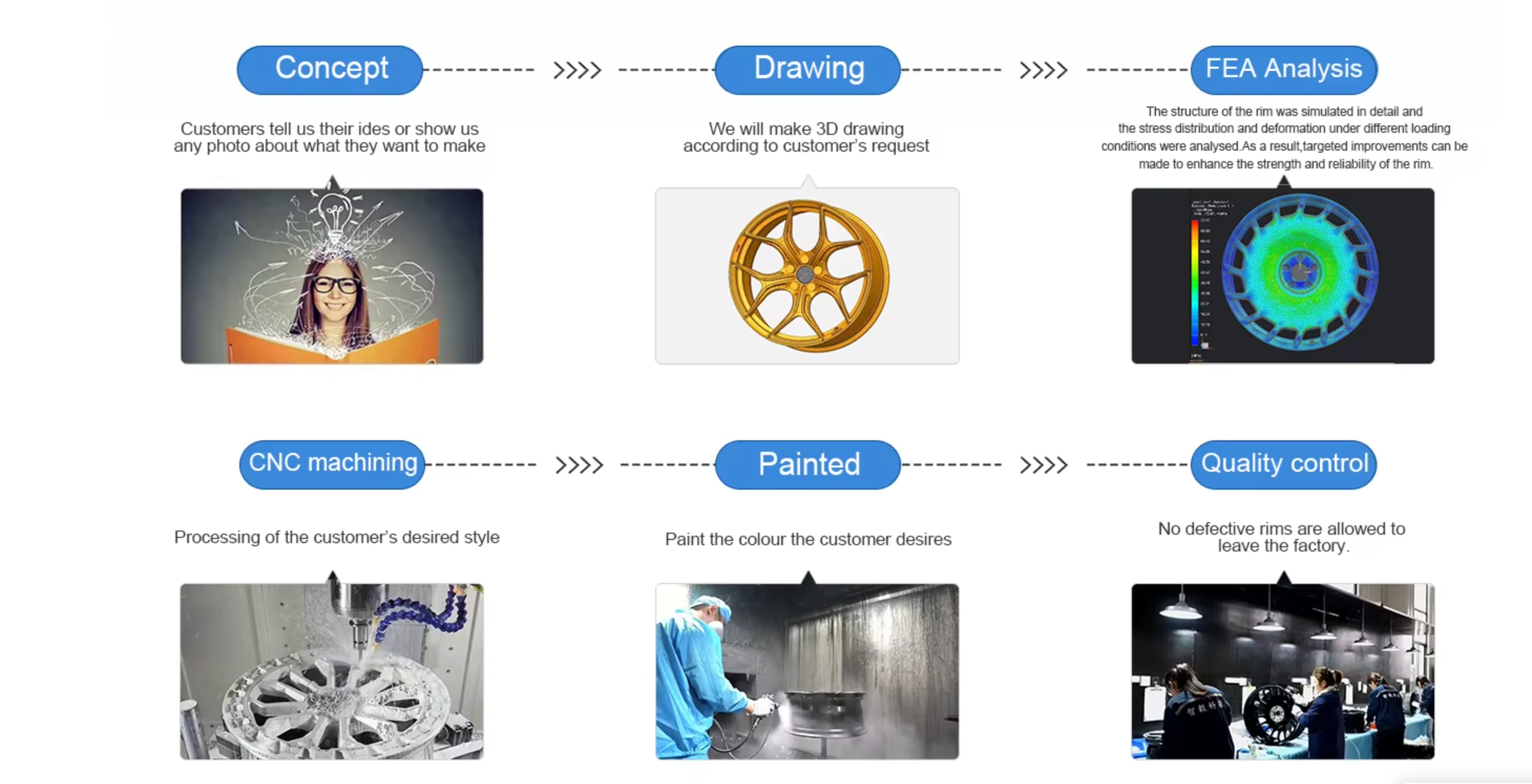

Painstaking care was taken in removing as much material possible while keeping material in critical areas to ensure complete safety and reliability. All areas of the wheels are considered and tested with FEA Analysis software and tested in both laboratory and real world conditions.

An example of how material is removed while key areas retain mass. In this case, we added forged mass to the inner rim to resist impact and bending.

We have partnered with some of the world’s premier aftermarket Big Brake kit suppliers and made sure that we clear your potential racing upgrades. All wheels are designed to clear from the design phase while maintaining max concave and good looks. Notice the raised rim barrel which allows for large diameter rotor and caliper combos.

We build wheels application specific. No wheels are thought to be set up for multiple cars like most manufacturers. We take into account the proper performance wheel and tire size and the aesthetic of the car to make sure that you not only perform good, you look good. Our 100% in-house production capability allows for this.