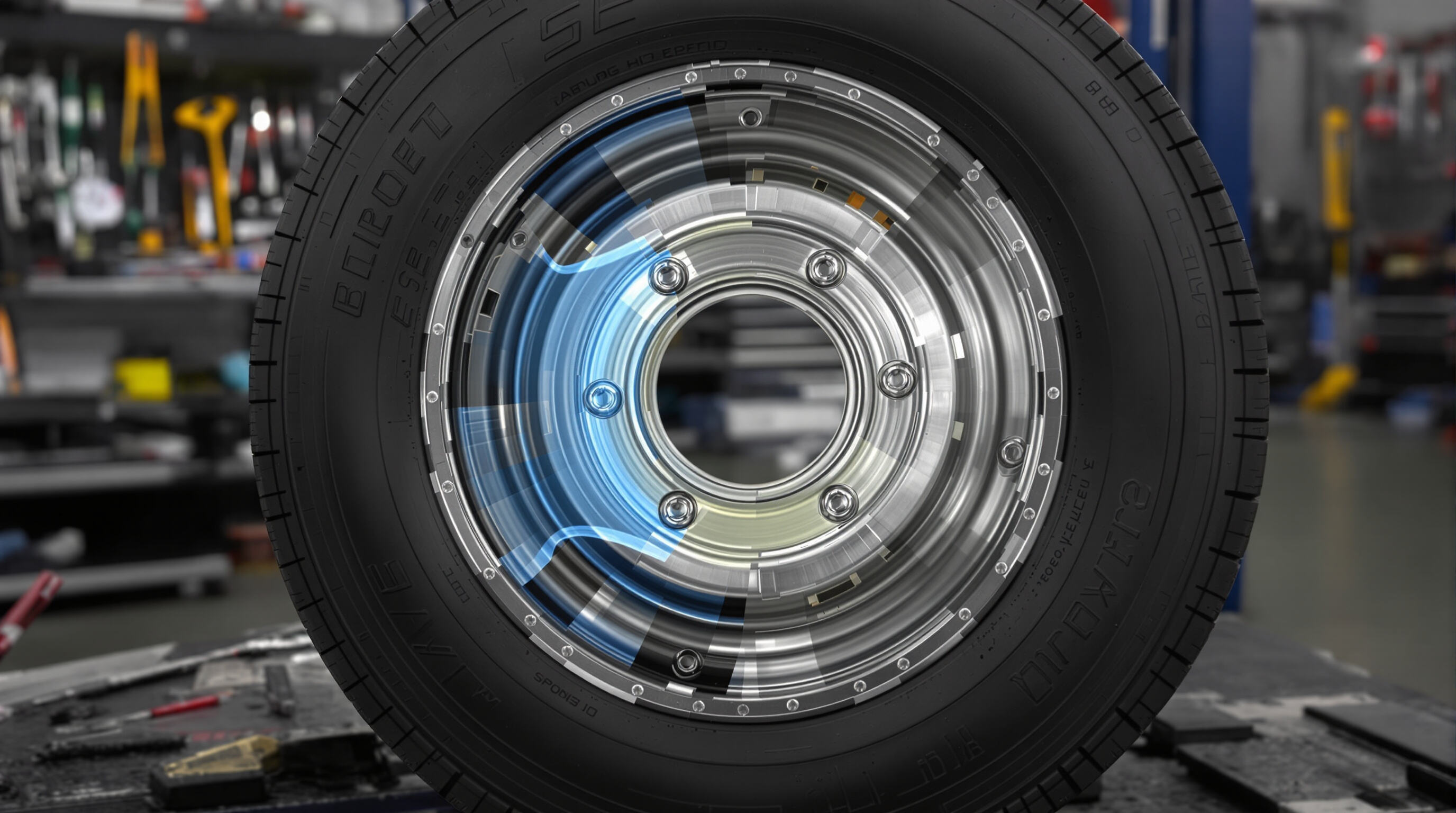

የቤድሎክ ማዕከሎች የሚያስተላለፉት የሚስማማውን የጎማ ቤድ እና የርንገት ገጽ ላይ ጭምር የሚያደርጉትን የልዩ የመታል ቅንጣት ያቀርባሉ። ማዕከሎች በተለምዶ በጎማው ውስጥ ያለውን አየር ብቻ ለመቆየት ይጠቀማሉ ነገር ግን በርካታ ጊዜ የመንገድ ውጭ በርካታ ጊዜ ይሰራጭሉ። በቤድሎኮች ተቋምተው ከሆነ ተጓዳኝ የጎማውን ግፊት እስከ ከ 5 እስከ ከሆነ 10 ፓውንድ በአራዱ ኢንች ድረስ መቀነስ እንደሚችሉ ነፃነት ይሰጣቸዋል። ይህ ዝቅተኛ ግፊት በሳንድ ወይም በሳንድ ላይ በመንገድ ላይ በጣም ጥሩ ጉዳት ይሰጣል እና በመሣሪያው ላይ ከተገኙት ጊዜዎች ጋር በጣም ተደጋጋሚ የሚከሰተውን የጎማውን መበላሸት እያደረገ ነው።

በታች ግፊት፣ ሲስተሙ ላይ የሚሠራውን በጭንቅላቱ ላይ የሚያሳርቅ ጎልቅ ኃይል 450 psi ሊበልጥ ይችላል፣ ይህም የመደበኛ ማዕከላዊ ማዕዘኖች የማይታጠቡበት ምክንያት ነው። በድንበር የሚጣበቅ ስርዓቶች በጭንቅላቱ ላይ በመተካት 1,100–1,400 psi ግፊት በማቅረብ ይህን ይቃወሙ፣ ይህም የጭንቅላቱን የማቆም ችሎታ በከፍተኛ ሁኔታ ይገነዳል። ፈተናዎች የጭንቅላቱ ስርዓቶች በተለመደው ሮለር ማዕከላዊ ማዕዘኖች ጋር ሲነፃፀር በ8 PSI የጭንቅላቱ ስህተቶች 80% ይቀንሳሉ ማለታቸውን አሳይነዋል።

| የይዞታ ክስተር | መደበኛ ማዕከላዊ (15 ፓሲ) | የቤድሎክ ማዕከላዊ (8 ፓሲ) |

|---|---|---|

| የጎላቅ ኃይል ችሎታ | 350 ፓሲ | 1,200 ፓሲ |

| ደህንነቱን የጎን ጠርዞች እጥፍ | ±30° | 55°-60° |

| የተራን የማጣቀሻ ችሎታ | መካከለኛ | ከፍተኛ |

በጎማ ግፊት በጎዳና ላይ 15 PSI በታች የሚውረድበት ጊዜ፣ በሜካኒካዊ ቅለም የተገጣጠመው የጎማ ጣት ምክንያት የሚንከባክብ የጎማ መጭመቅን የሚቀንስ ሲሆን ይህም የሚያሳየው የቤድሎክ ጎማዎች በከባድ ቦታዎች ላይ እንዴት እንደሚሰሩ ነው። ይህ የጎማ መሳሪያ የሚሰራው በዋናው የጎማው ክፍል እና በቦልቶች ጋር የተያዘ ሌላ ቅንጣት መካከል የጎማው ጣት በማስገባት ነው። ይህ አቅራቢያ በ2023 የተካሄደ ፈተና በታወቀው የመሳሪያ ጎማዎች ጋር ሲነፃፀር የቤድሎክ ጎማዎች እንዴት እንደሚሰሩ በትክክል አሳይቷል። የተለመዱ የጎማ መሳሪያዎች በከባድ ሁኔታዎች ውስጥ በተደጋጋሚ በ93% የበለጠ የሚውሉ ሲሆን ይህም የኦፍሮድ አውታሮች በከባድ ሁኔታዎች ላይ ይህንን የመሳሪያ መጠቀም የምታሳስበው ምክንያት ነው።

በሞአብ ውስጥ የሚገኘው በሆቴው ሀይለኛ ማዕከል ላይ የተካሄደው ምርመራ የ40 ብሮኑ መኪናዎች ላይ በተከናወነበት ጊዜ፣ በ8-10 ፓሲ አየር ግፊት ላይ የሚሰበሩ በድሎች ጎማዎች ምንም ትንታኔ አሳይቶ አልነበረም። ከመደበኛ ጎማዎች ጋር ሲነፃፀር ይህ በጣም አስገራሚ ነው፣ የ trail OCR 8+ ክፍሎች ላይ በመሸከም ጎማዎች ከሁለት ሶስተኛ በላይ (ከ68% በላይ) ትንታኔ አሳይተዋል። ዝቅተኛ ግፊት በመጠቀም ተገኝቶ የጎማው ተያያዥነት አካባቢ በግምት 22 በመቶ ተስፋፋለ። ይህ ለመሳብ አካባቢው ይዘት ከፍተኛ ስለሆነ ጭንቅላቱ በተሻለ መንገድ ይቆያል። እንዲሁም የተገናኙት በድሎች በጣም ትክክለኛ እና ተመራጭ የስተርሪንግ ሁኔታ ይቆያሉ፣ ይህም ለእያንዳንዱ የሮክ ክሮልር በጣም አስፈላጊ ነው ለወገኖች ላይ ሲንሳፈፍ ማድረግ የሚሞክሩ የተለመዱ ጎዳናዎች ላይ።

| ስፌሪዮ | የቤድሎክ የውድቀት መጠን | የመደበኛ ጎማ የውድቀት መጠን |

|---|---|---|

| የጎን ቁልቁል >25° በ10 PSI | 3% | 57% |

| የጠንካራ አፋር ተጽዕኖ | 1%* | 82% |

| የጠንካራ ኅጡ ማስገቢያ | 0% | 41% |

*የጎን ጉድለት ብቻ ነው የሚከሰተው በተሳሳተ አቀማመጥ ወይም በጥላ ቴክኒክ ሲሆን

ይህ የሚታወቅ የደህንነት ርዝመት በቴክኒካዊ ቦታዎች ላይ የቢድሎክ ጥቅማ እንደ መሸከም እንደ አማራጭ አገልግሎት ያሳያል፣ የመቆራረጥ ጉድለት ማለት የመቆጣጠር ጉድለት ማለት ነው። የአዲስ ዲዛይኖች የመጫኛ ጥንካሬን በ 40% ይቀንሳሉ ሲነፃፀር ከአሃዛዊ ምርጫዎች፣ እና እንዲሁ የአንዳንድ የዲ.ኦ.ቲ. ጥቅሞች የሚቆዩበት በማስወገት የሚቻል የመንገድ ማስቻል ተስማሚነት ይቆያሉ።

በተንታኝ የሳንድ ተራሶች ላይ ሲመኝ በድንገተኛ አየር ግፊት መቀነስ ምክንያት በነበረበት ጊዜ በድንገተኛ መንገድ ተሽከርካሪዎች ከመበላሸቱ ይጠብቁበታል። ይህንን ለማድረግ የሚችሉት ምክንያት ምንድን ነው? የሜካኒካዊ ቅለጥ ስርዓቱ ተሽከርካሪዎች በደህና አየሩን እስከ 4-8 ፒኤስአይ ድረስ መለቀቅ ይችላሉ፣ ይህም ለተጠቃሚው ለመከራራት ላይ የተረጋጋ ጎማ ጥብቅ መያዝ አስፈላጊ ነው። በቅርቡ የተደረገው የባህር ባህሪ በ2023 ዓ.ም. የተሰራ ሳንዳዊ የፒስተር ቡድኖች ላይ የተካሄደ ጥናት ከአንድ አስተማማኝ ቡድን ጋር ተመሳሳይ ሁኔታዎች ላይ የተመሳሰሉ ችግሮች 40 በመቶ ያነሰ እንደሆኑ አሳይቷል። ሌላ አስፈላጊ ጥቅም ደግሞ በጣም ቀጥታ ጎኖች ላይ የሚገኝ የሳንድ አይነት ነው፣ ይህ የተለመደው ጎማዎችን ለመቁረጥ ይሞክራል። በዚህ ሁኔታ ጎማው በተገናኘበት መንገድ ምክንያት በጎማው አጠገብ ላይ የሚፈጠረው ጭንቀት በጣም ዝቅተኛ ነው።

የታሮዎች እንደገና አየር ግፊት ሲያጣር በተመች ወለድ ላይ በጣም የሚያሳሩበት ነው፣ ይህም ሲሆን የመገጣጠሚያ ክፍሉን በሶስት ጊዜ ሊያሳራ ይችላል። በታሮው ውስጥ በእያንዳንዱ አራት ሳንቲሞች ውስጥ በቀጥታ 6 ጣሊያ የሚሸጋገው (የተለመደው የታሮዎች የሌለው ነገር ነው ይህን የማያቋርጥ በመሆኑ)፣ እነዚህ ደበተኛ የ35 ኢንች ዘንጎች ታችኛው ክፍል ላይ በግምት 12 ኢንች ያህል ይሰፋሉ፣ ይህም እንደ የባህር መንገድ ላይ የሚንሸራተት ስርዓት ይፈጥራል። ውጤቱ? የመሬት ግፊት በከፍተኛ እና በግምት ከ15 ጣሊያ ወደ ከ4 ጣሊያ ድረስ ይወሰናል፣ ይህም የሚያደርገው የማሽኑ ማዳዎች በተለመደው የሚሽከረከሩበት መንገድ ይለወጡትና እንደ ትልቅ ማዳዎች ይሰራሉ የሚያስቸግሩት እንደ የባህር መንገድ ላይ የሚንሸራተት ሁኔታ ላይ ነው። በተለያዩ ዜጎች ውስጥ የተካሄዱ በርካታ ሙከራዎች የሚያሳዩት በቤድሎክ የተሰራው መኪናዎች በግምት ከአንድ አምስተኛ ያነሰ ትራሮ መግፋት እንደሚያስፈልጉ ነው የሚያሳዩት፣ ይህም ማለት የሞተር አካላት ላይ ያለው ጭንቅላት እንዲቀንስ እና በጣም ረጅም የኦፍ-ሮድ ጉዞዎች ወቅት በጋዝ መጠን ላይ የሚታየውን ትኩረት እንዲያሳዩ ማለት ነው።

በባጃ 1000 ውስጥ አስተማማኝ ቡድኖች በተደጋጋሚ የሚሄዱት 3–5 PSI በበርካታ ምይ 150 በርቃታ ላይ እና በሲልት መስታዎች ላይ. የመካኒክ አሳ_failure ዳታ የእነር reliability ጥሩ ውጤት ያሳያል:

| Component | የቤድሎክ የውድቀት መጠን | የመደበኛ ጎማ የውድቀት መጠን |

|---|---|---|

| የጎማ ምሰ መለየት | 0.8% | 31% |

| ተበታተነ የጎማ ጠር | 2.1% | 17% |

በየድት የመቆም ችሎታ 38:1 በመሆኑ፣ በፕሮፌሽናል ዜጋ ማራዘም ውስጥ በድት ማስቆሚያዎች የተሰጡ ናቸው፣ እዚህ ላይ አንድ ተሳስተው የሄደ መተረጎም በመልሶ ማግኘት እና የጊዜ ክፍያ በላይ በሆነ 7,500 ዶላር ዋጋ ይሰጣል።

የፋይል ውስጥ የመስታወት ስርዓቱ የሚሰራው በተለያዩ የጎማ መቆለፊያዎች ውስጥ የሚገኙትን የማቆም ማስታወቂያዎች በመጠቀም ነው፡፡ ይህ ማለት የጎማውን መጠን በትክክል ለማስቀመጥ ብስክሌቶች ሁሉን የጎማ ስብራቶች መቀየር አያስፈልገውም ገና በጎማው ላይ ሲወድቁ ይህንን ያስችላቸዋል፡፡ የተወሰኑ ሞዴሎች የመጨረሻውን ደረጃ በመጠቀም የቦልት ያልተገናኙትን የማሰሪያ አይነቶች ይጠቀማሉ ይህም የሚያደርገው በውጭ ቦልቶች ቀልጣፋ የፕሌት መጭመቅ ነው፡፡ ይህ በራሱ የጎማውን መጠን ያስቀምጧል ሲል በጣም ዝቅተኛ ግፊት ላይ ማስኬድ ይችላሉ አንዳንድ ጊዜ 8 ፒኤስአይ ድረስ ሲደርሱ የጎማውን መጥፋት አያስፈልገውም፡፡ የገንዘብ ብድሮ አካልም በጣም ጥሩ ነው፡፡ በዚህ መቀየር ላይ የተወሰኑ ሰዎች በመጠን 40 እስከ 60 በመቶ የሚቆረሰውን እንደ አዲስ በር የመስታወት ጎማዎችን መግዛት ነው፡፡ ይህ ምክንያት ነው ለዚህ አዘገጃች በርካታ የጎማ ማሽከርከሪያዎች በዚህ ዘመን መቀየር የሚያሳዩት፡፡

| ካልኩላቶች | የቦልት ያልተገናኙት የማሰሪያ ስርዓቶች | የተለያዩ የመስታወት ግንኙነቶች |

|---|---|---|

| የማሰሪያ ጊዜ | 45-60 ደቂቃዎች | 90-120 ደቂቃዎች |

| ከፍተኛ ግፊት ጥበቃ | 15 PSI የተቆየ | 5 PSI የተቆየ |

| የመስታ ተጽዕኖን መቋቋም | 500–700 ሰዓታት (ሳንድስቶን) | 1,000+ ሰዓታት (ሳንድስቶን) |

| የዲ.ኦ.ቲ መንገድ ጥበቃ | አነስተኛ ክልላት | የማይስማማ |

ቦልት ያልተገባባቸው ሰርዓቶች ፈጣን እና ቀላል አዘጋጆችን ይሰጣሉ ግን ለአነስተኛ የባህር ጉዞች ብቻ ተስማሚ ናቸው፣ ወደ መጀመሪያው የክላምፕ ዓይነት በድል የተገናኙት ግን ለከፍተኛ ቅርፅ ሁኔታዎች እንደ ፕሮፌሽናል ጋራ መሸከም ሁልጊዜ የተሻሉ ይሆናሉ።

የማይስተካከሉ ባዶ ማቆሚያዎች የቅድመ-ተሽከርካሪ መሳሪያዎችን እና የመሬት ትንሽ ቅዳሴ መሳሪያዎችን በመጠቀም የዲ.አይ. መጫኛን ያቀላጥማሉ። ግን ግን 22 ግዛቶች የመንገድ ጥቅምን ለማስቀረት የመንገድ መንግስት (ዲ.ኦ.ቲ.) የመሽከርከር መዋቅር ህጋዊ ገዢዎችን ስላይከተሉ አይፈቀዱም። በ2023 ዓ.ም. ውጭ መንገድ ህጋዊ መመሪያዎች ጉዳዩ የተባረረበት 78% የበለጠ አካባቢዎች የበለጠ አስተማማኝ መጫኛ ማረጋገጫዎች የተሻለ አስተሳሰብ ያሳያሉ።

በተሻለ የተሰራ ቅለጫ ድርድሮች ምክንያት በቅድሚያ የነበሩት በድርጅቶች ከዚህ በፊት የነበሩት በድርጅቶች በወለዱ ግብረ መረት የተሰናዱት በአሁኑ ጊዜ በተለያዩ ነጥቦች ላይ የሚተገበረውን ግፊት በመስፋፋት የታሬውን የመተላለፍን ችግር በከፍተኛ ሁኔታ በመቀነስ የታሬውን ግፊት እስከ ሶስት ፓሲካ ድረስ የሚያሳድጉ ነው፡፡ በአማችው የተካሄዱት የመስክ ፈተናዎች በጣም አስቸኳይ የሆኑ የመንገድ ሁኔታዎች ላይ በአሁኑ የተሰናዱት በድርጅቶች በቅድሚያውኑ የነበሩት በድርጅቶች ጋር ሲዟዳጅ በ90% የታሬውን የመተላለፍን ችግር በከፍተኛ ሁኔታ በመቀነስ የሚያሳድጉ ነው፡፡ ይህ ምክንያት አሁን የሚታወቁ የመንገድ ማሻሻያዎች በብዛት መቀየር አስፈላጊነቱን ያሳያል፡፡

የታሬውን መያዣ የተከታታይ ልማት ለሱላዊ ወርቃዊያን የተጠቀሰ ነው፡፡

ቅርብ ጊዜ የተደረገው አሻራት ቲፒኤምኤስ ሴንሰሮች ጋር የተ תאመ እና አየር ማናቸውን የምስክር አሉሚኒየም ያሉ ዉዝ አነስተኛ የሚሆኑ ቁሳቁሶችን ያቀፍላል።

የቢድሎክ ሰYSTEMS እንደ ከባድ መንገድ የደህንነት ችግሮች ምክንያት በማዕከላዊ ቅዱሚዎች በጥብቅ ይመረመራሉ ይልቁንም ኦፍ-ሮድ ሰዎች በተግባር የታሬዎቻቸውን በዝቅተኛ ግፊት ላይ ለመስራት እንዲችሉ ይፈልጋሉ የሚል ጥያቄ አለ። ከዚህ ሁለት ቡድኖች መካከል የሚደረገው ውይይት በስትሪት ሊገል የሚችሉ አማራጮች ውስጥ የተወሰኑ አዲስ አገልግሎቶችን እንዲኖር አድርጓል። እነዚህ አዲስ አቀራረቦች FMVSS ገበያዎችን ማሟላት ይችላሉ እና ተስማሚ አፈጻጸምን ይሰጣሉ። ለምሳሌ ስፕሊት ሪም ዲዛይኖች አሁን በባዶ ወለያዎች ላይ ለግፊት በኩል ለ15 ፒኤስአይ ተያያዥነት ይሰጣሉ እና ዶ.ቲ. በደረጋገጠው ለ100 ሰዓት የሚቆይ የመተካት ፈተናዎችን ማሟላት ይችላሉ። ስለዚህ ኢንዱስትሪ ምንጮች ሁል ጊዜ ላይ ላይ እንዲያውቀው ይቀጥላሉ።

በዕቅዶች ምክንያት ብዙ ባዶች የመንገድ ጥቅማቸው ከደንበኛ ጥቅሞች ጋር አይዛመዱም። ከዚያ ግን በስዕል ሊቀለበት የሚችሉ የመንገድ ህጋዊ ባዶች ጋር የተሻሉ የአዲስ አቅም ባዶች አሉ።

አዎ፣ ውስጥ እና የሌለው ባዶች መፍትሄዎች አሉ ይህም በአሁኑ የማዕከላዊ ማዕከላዊ ስርዓቶች ውስጥ ማስኬድ ይቻላል።

ዝቅተኛ የማሽከርከር ግፊት ማሽከርከር የማሽከርከር ጎኖችን ይዘት ይጨምራል፣ በባህር ሁኔታዎች ውስጥ ተያያዥነትን ይጨምራል እና የባዶ ግንኙነት አይጠፋም።

ባዶች የተደበደቡትን ጊዜ በጊዜ ማረጋገጥ እና የመሳሪያዎች ጥራት ማረጋገጥ ይጠይቃሉ፣ ነገር ግን የማስጀመሪያ ሂደቱም ቀላል እና ያነሰ ውዝግና ነው።